Chemical resistant coatings are specialized paints or finishes that are designed to resist corrosion from chemicals. They are often used in industrial and commercial settings, where they can protect metal surfaces from exposure to corrosive chemicals. Chemical resistant coatings can also be used in residential settings, where they can provide protection for metal surfaces exposed to household cleaners and other harsh chemicals.

There are a number of different types of chemical resistant coatings available on the market, each with its own advantages and disadvantages. Selecting the right type of coating for your needs will depend on the specific chemicals you need to protect against, as well as the surface you need to apply the coating to.

Here are a few tips for using chemical resistant coatings: or even failure of the coating.

1. Read the manufacturer’s instructions carefully before use. This will ensure that you are using the coating correctly and will help you avoid any potential problems.

2. Make sure that the surface you are applying the coating to is clean and dry before beginning. Any dirt or grease on the surface can reduce the efficacy of the coating.

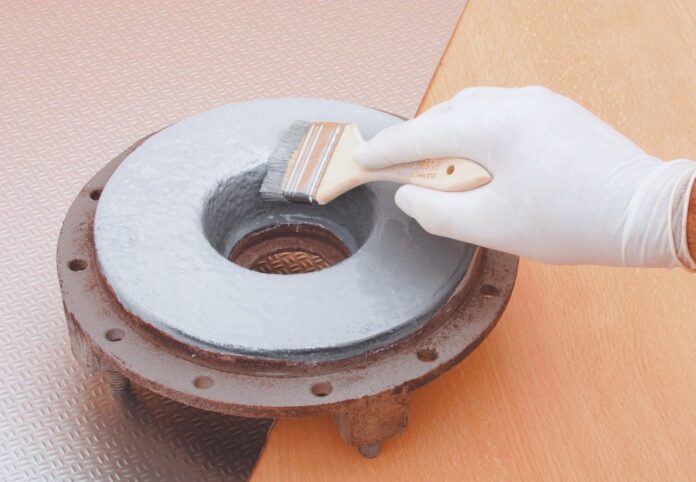

3. Apply the coating evenly and smoothly. This will help ensure maximum coverage and protection.

4. Allow the coating to dry completely before exposing it to chemicals. This will help prevent any damage to the coating from exposure to the chemicals. Chemical resistant coatings, optically clear, can be applied to a number of surfaces in order to protect against corrosion from chemicals.

Considerations for Using Chemical Resistant Coatings

When it comes to choosing a chemical resistant coating for your project, there are a few things to keep in mind. Here are a few tips to help you choose the right coating for the job:

1. Know the chemicals you’ll be using. The first step is to identify the specific chemicals that will be present during your project. This will help you narrow down your options and choose a coating that is specifically designed to resist those chemicals.

2. Consider the environment. It’s important to think about the environment in which the coated surface will be exposed to chemicals. Will it be outdoors? Indoors? In a highly corrosive environment? Knowing this will help you choose a coating that can withstand the specific conditions.

3. Choose the right type of coating. There are many different types of chemical resistant coatings available on the market, so it’s important to choose one that is suited for your specific needs. If you’re not sure which type of coating to choose, consult with a professional for guidance.

4. Follow the manufacturer’s instructions. Once you’ve selected a chemical resistant coating, be sure to follow the manufacturer’s instructions for proper application and cure times. Failure to do so could result in poor performance and/or damage to the coated surface.

Cleaning and Maintenance of Chemical Resistant Coatings

It is important to regularly clean and maintain chemical resistant coatings in order to extend their lifespan and ensure their efficacy. Below are some tips for doing so:

1. Use a soft brush or cloth to remove any dirt, dust, or grime that has accumulated on the coating.

2. If the coating is particularly dirty, you may need to use a mild soap or detergent to help loosen and remove the dirt.

3. Rinse the area thoroughly with clean water after cleaning.

4. Inspect the coating regularly for any signs of wear or damage. If any damaged areas are found, repair or replace them as soon as possible.

Conclusion

Chemical resistant coatings are a great way to protect your surfaces from damage.

Whether you’re using them for industrial or residential purposes, these coatings can help you keep your surfaces looking like new. We hope that our tips have helped you figure out how to use these coatings and why they’re so important.