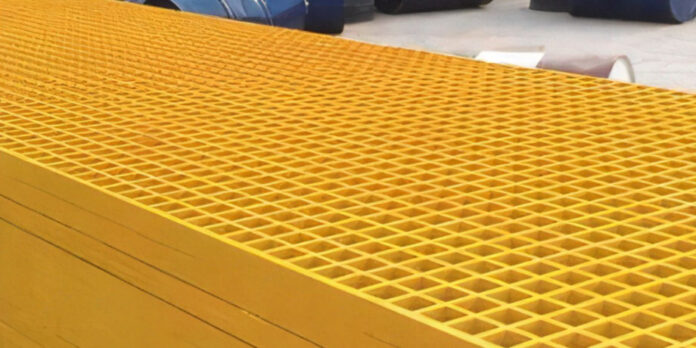

Keeping our employees safe is going to help present our brand as a trustworthy one, it is going to help get new clients, and it is going to protect our business from any liability claims. There are many ways that you can keep your workers safe, and GRP grating is one of them. Here, we are going to tell you how GRP can improve your workplace safety, and we are going to list some of the main reasons why you should implement it in your firm.

Decreased slipping hazards

One of the biggest hazards in any factory or construction site is slipping. No matter if it is because the surface of the floor was too slippery on its own, or because there was water or something else spilled on it, it has been reported that most accidents in a workplace happen because of slips.

When you implement GRP grating in your factory, you are going to minimize these hazards, since this material is going to allow all liquids to pass through it, and it will allow the surface to stay dry and non-slippery at all times. This is going to help protect your employees and clients and it is going to create a better and safer working environment.

It is more durable

Wear and tear are another reason why workers get injured and when there is something that is not glued properly, or part of the flooring is sticking out, your employees are more likely to trip and fall. The last thing you want to do is create an environment where your team has to learn all the hazardous places so that they can avoid them and you should make sure that they feel safe even when they are in a rush.

GRP grating on its own is extremely durable, and even if wear and tear happen, the structure is still going to stay intact and it will not pose a tripping hazard. Even though you will have to maintain and even replace the surface, the time for that will not come in the near future.

It is non-corrosive and non-conductive

When working with high-risk materials, electricity, heat, or water, we are aware that all those things can easily lead to injuries. Even though there is no possible way to prevent any of the possible issues that can arise, there are still ways that we can minimize the hazards.

The GRP surface is non-conductive, which means that even if it comes in contact with electricity, it will not conduct it, meaning that the risk of electrical shock is almost non-existent. On the other hand, it is also non-corrosive, and even if your employees have an accident and they cut themselves, they won’t have to worry about all the problems that can arise from cuts from corrosive surfaces.

Overall, this material is far better for keeping your brand’s safety on the highest level, and you will know that you have done everything in your power to keep your team safe. Do as much research as possible about this material, and for yourself why implementing it in your offices is going to be one of the best decisions you’ve made