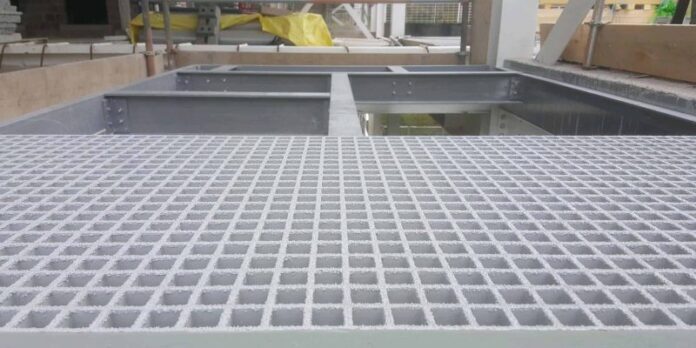

GRP Riser Grating provides additional security for all high-traffic areas. Contractors who work in such places, at different levels of the floor, can do their job without interruption. However, it must be properly specified and installed.

1. Load and range

There are many different factors that affect the final outcome of a project, but the most important items to consider are load and range. So, you need to understand what materials you should use. Check their performance, but don’t forget to think about prices. The degree of carrying capacity will depend on the type of use and the weight of the equipment installed on it.

Range refers to the length of the component that extends between the two girders. So before you buy, measure your spans and calculate the load that will carry your floor. For example, there is a point load that acts on a small or concentrated surface. There is also a UDL that refers to an evenly distributed load in a defined area.

2. Specifications and performance

GRP Riser Grating is a very strong material, but also lighter than steel and similar metal alternatives. This means that it can withstand heavy loads in industrial areas with large shocks. It is a perfect ratio of strength and weight, excellent load capacity. It is resistant to weather conditions, fire and acid. It is multi-purpose and easy to maintain.

3. Maintenance

Find GRP gratings that are easy to pick up, transport, install and maintain. Thanks to their low weight and design, they are very easy to maintain. As we mentioned earlier, they are resistant to most external influences, which means that you will enjoy them for more than 20 years. That is why more and more people are opting for these gratings. These are people who come from different industrial fields. These are architects, developers, site managers and many others who need support for their service floors.

4. Security

In addition to the high level of durability, this material does not spark, which means that it is an equally good choice for all places that involve high temperatures. No handling required and heavy lifting equipment. You also do not have to have a work permit and there is no risk of fire. Best of all is that it is very flexible. For example, even if you opt for larger dimensions, you don’t have to worry. All you need to do is choose the desired shape, cut it and it will match the layout of your room. Of course, if you hire experts and a reliable company, they will do it for you. Most companies will be happy to meet you and provide pre-cut parts so you can easily fit them into your space or they will install them. It all depends on your decision.

Conclusion:

GRP Riser Grating is a very cost-effective and customizable solution if installed correctly. As a result, you get a safe and light surface that will allow you to perform work without problems. It is also corrosion resistant and extremely durable. There is no danger of slipping and it is an ideal choice for any environment. Forget about expensive security barriers, because GRP will provide you with the right work platform for your staff.